Though people prefer manual labor in many ways, but not everywhere their work wonders. You can’t rely on manual power to help you with an automatic monitoring or tracking system. They work in shifts, so there’s a danger they won’t get enough interaction. When you first started focusing on automation systems, it made your difficult times easier. You might begin by repairing the agv hk to increase performance. If you go for the top providers, they will come and fix it for you and place it where you need it by adding the features that your working area requires.

If you’re going to attempt it for the first time for agv systems, here are some benefits to be aware of:

- It lowers the amount of money you have to charge for labor.

- They repair the harm produced by products and structures.

- The level of occupational safety is raised at a lesser cost.

- Once you’ve fixed the automation system, it’ll make your life easier and happier.

- The primary function of agv is that it can be simply operated 24 hours a day, seven days a week. When the right level of maintenance is provided, it does not become damaged.

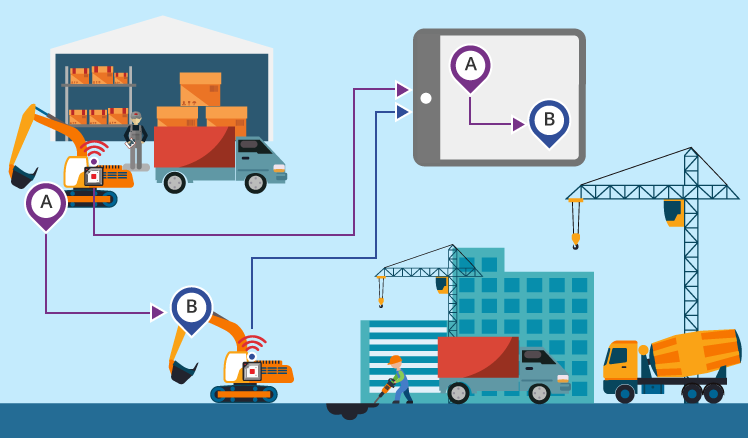

- If it’s connected to the warehouse, the control system can be utilized to track records automatically. The cost of the people who perform inventory reports is steadily reduced as a result of this.

When you combine the above capabilities with some additional technology for obtaining help, you can simplify your working process. The materials are tracked using the asset management rfid tags. It works more quickly and saves you a lot of time. This technique aids in the improvement of data accuracy as well as implementing safety features. Used to increase income and speed up the process by lowering the time to despatch and deliver goods. For speeding up the process and reducing personnel, almost both strategies are applied.